INTRODUCTION

|

| Figure 1 |

Bearing internal clearance is the gap between a ring and rolling element assembly, and the rolling surface in other ring (figure 1), it represents the relative motion that can take place between both rings. Depending on the type of bearing, internal clearance can be radial or lateral, and it plays an important role in the smooth, efficient and long lasting operation of gears. It is therefore important to understand how gear manufacturers specify bearing clearances and the effect of shaft and housing fits, and temperature on the actual clearance in operating conditions. While it is essential for anyone who handles bearings to follow proper practices, covered in detail by manuals published by many bearing manufacturers, it is also important for maintenance personnel to be aware of the impact of bearing mounting practices on gearbox performance. This article deals with the way in which free state bearing internal clearance, shaft and housing fits, mounting practices and operating temperatures determine actual operating clearance during and its implications on gearbox performance.

BEARING TYPES

|

| Figure 2 |

|

| Figure 3 |

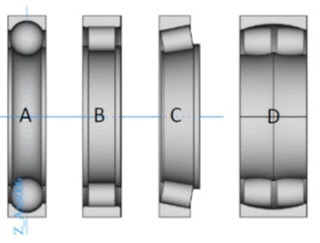

Bearings can also be classified by the shape of the rolling elements: balls (A), cylindrical rollers (B), tapered rollers (C), or spherical rollers (D).

|

| Figure 4 |

The complete bearing type description includes both classifications, e.g. tapered roller thrust bearing.

BEARING INTERNAL CLEARANCE

For radial bearings, the gap between the rolling elements and the outer race is called radial internal clearance and it is equal to the possible relative motion between the inner and the outer race in the radial direction (figure 1).

|

| Figure 5 |

The allowable lateral displacement of a rotor supported by a thrust bearing arrangement is called end play or lateral clearance.

Angular contact ball bearings and tapered roller bearings have both a radial and a lateral clearance directly related to each other. Lateral clearance is easier to control, and it is, therefore, more often specified for these bearings.

FACTORY SET CLEARANCE.

Radial internal clearance for radial ball, cylindrical and spherical roller bearings is set at the factory when bearings are assembled. The most common practice is to follow ISO standard 5753, using the C classification code:

Normal radial clearance, C0;

Smaller than normal, C1 and C2; and

Greater than normal C3, C4 and C5.

EFFECTS OF MOUNTING FITS ON RADIAL CLEARANCE

Manufacturing tolerances for outer and bore diameters are usually specified per ISO standard 286 that designates tolerances per diameter range using a letter and a digit, lower case letters designate outer diameter tolerances and capital letters designate bore diameter tolerances. For example, an m6 specification for a 100 mm shaft diameter, which falls within the “over 80 mm up to and including 120 mm” range, prescribes a +13/+35 micrometer tolerance, i.e. 100.013/100.035 mm shaft diameter. Likewise, an H7 specification for a 180 mm bore prescribes +0/+35 micrometers tolerance or 180.000/180.035 mm bore diameter.

The actual fits for a particular bearing’s shaft and housing will fall within the range allowable by the manufacturing tolerances of the mating components. Let’s assume, for example, that an m6 shaft and an H7 housing are specified for a standard 23220 spherical roller bearing with a 100 mm (-0.020/+0 micrometer tolerance) bore and a 180 mm (-25/+0 micrometer tolerance) OD.

The Bearing OD to housing fit will fall within the range:

Max Housing Bore

|

180.035

|

Min Housing bore

|

180.000

| ||

Min Bearing OD

|

179.985

|

Max Bering OD

|

180.000

| ||

Fit from

|

0.050

|

Loose

|

To

|

0.000

|

loose

|

The bearing bore to shaft fit will fall within the range:

Max Bearing Bore

|

100.000

|

Min Bearing Bore

|

99.980

| ||

Min Shaft diameter

|

100.013

|

Max shaft diameter

|

100.035

| ||

Fit from

|

-0.013

|

(Tight)

|

To

|

-0.055

|

(Tight)

|

|

| Figure 6 |

Loose fits have no impact on bearing internal clearance. Depending on the ring thickness, tight fits reduce radial clearance by 50 to 80% of the interference when mounted on solid shafts or thick housings. The rings in bearing 23220 are in middle thickness range so internal clearance will be reduced by approximately 60% of the tight fit between the shaft and the bearing. In this case, from 7.8 to 33 micrometers. Assuming, further, that a C3 internal clearance is specified for this bearing, the clearance would be from 100 to 135 micrometers in the free state. After mounting with the inner race interference fit, the radial clearance will be from 67 to 127.2 micrometers.

Free state internal clearance (C3): 100 to 135

Shaft tight fit (m6): 13 to 55

Reduction of internal clearance (60% of tight fit): 7.8 to 33

Internal clearance after installation: 67 (100-33) to 127.2 (135 -7.8)

Dimensions in micrometers

CAUTION: a loose ring fit in applications where the ring rotates relative to the load may allow the ring to slip or creep around the shaft or housing, generating heat. In severe conditions the corresponding temperature increase may reach levels that could eventually destroy the bearing.

LATERAL CLEARANCE

SINGLE ROW BEARINGS

Lateral clearance for single row angular contact ball or tapered roller bearings is set during gearbox assembly (Figure 5):

1. The complete shaft assembly, including the outer rings is lowered into the bottom half of a split housing (figure 7);

2. One end plate is fixed to the housing;

3. The other end plate (A in figure 5) is bolted on with no shims or gaskets and the gap is measured (C in figure 5); and

4. Shims are placed in gap, C, to provide the desired lateral clearance.

|

| Figure 7 (courtesy of Hoesburgh and Scott Co.) |

Since lateral clearance is set after the inner rings or cones have been mounted on the shaft, it is not necessary to account for the loss of internal clearance due to the tight shaft fits.

DOUBLE ROW BALL AND TAPERED ROLLER BEARINGS

|

| Figure 8 |

The bearing gap at cero clearance is the base dimension.

The spacer thickness is then set to give the desired clearance or preload (with spacer thickness smaller than the gap)

Angular contact ball bearings may be manufactured as a double row unit with the internal clearance set at the factory. It is more common, however, for precision angular contact ball and tapered roller bearings to be supplied as sets in which the lateral clearance (or preload) is controlled by the width of the bearing rings and spacers.

LOSS OF INTERNAL CLEARANCE DUE TO THREMAL EXPANSION

The heat generated by rolling friction in the bearings is commonly dissipated into the atmosphere or removed through a water-cooled bearing housing. Therefore, shafts generally run several degrees hotter than bearing housings. This temperature difference translates into a greater thermal expansion of the shaft relative to the housing, reducing the operating radial internal clearance.

While the gearbox is running at normal operating load, the casing is usually cooler than the shafts. This means that the shafts will also have a greater thermal longitudinal expansion than the housing. When the shafts are supported by bearings that can only carry thrust loads in a single direction, such as thrust bearings, single row angular contact ball or tapered roller bearings, the bearing rings at both ends of the shaft are fixed to the housing and there will be a reduction in the lateral clearance of the support system (Figure 5).

|

| Figure 9 |

Shafts may also be supported by bearings that can carry thrust loads in both directions, such as double acting thrust bearings or double row angular contact ball, tapered or spherical roller bearings. For shafts supporting helical gears, one of the bearings must be fixed to the housing to carry the thrust load in either direction, while the other bearing must be allowed to float, i.e., to be displaced in the lateral direction to accommodate for differential thermal expansion between the shaft and the housing.

The tooth shape of double helix and herringbone gears forces a set of meshing gears to find their lateral position relative to each other, therefore, only one bearing can be fixed and all other bearings in the gear train must be allowed to float.

NOTE: shafts in gear sets with small thrust loads are sometimes supported by single row radial ball or spherical roller bearings that can withstand limited thrust loads. These bearings may be mounted in a fixed-float arrangement or, when the span between bearing supports is small, with both bearings fixed.

BEARING PRELOAD

Instead of internal clearance, bearings can be preloaded with an interference fit between the bearing races and the rolling elements. A preload can be created during assembly or it can be the result of a differential thermal expansion between the shaft and the gearbox casing. High precision angular contact bearings are supplied in sets with a factory established preload. These sets must be kept as units, combining components of different sets will alter the preload set at the factory and adversely affect performance and life expectancy of bearings and gears.

INTERNAL CLEARANCE AND GEAR PERFORMANCE

As the internal clearances increases, so does the possibility of shaft movement within the supporting bearings. This condition may have a negative impact on gear life and it may represent a problem in applications subject to oscillating loads or vibration, especially in high speed applications.

IMPACT ON BEARING LIFE

In a bearing operating with a large internal clearance (I), only a few rolling elements carry the load at any given time. This means that the contact stresses on bearing races and rolling elements are high. As the clearance decreases (II – III), a larger number of rolling elements share the load in an area called the load zone, reducing contact stresses, which translates into an increase in bearing life. This holds true up to a slightly preloaded condition (IV), beyond this point, the stresses due to the preload will drastically reduce bearing life (V). Unfortunately, it is practically impossible to predict the exact operating internal clearance, and trying to achieve the ideal operating preload with a load zone slightly greater than 180° (IV) comes at great risk of creating a 360° load zona leading to premature failure (V). For this reason, the common practice, except for high precision or high-speed applications, is to let bearings operate with a slight clearance and a 90° to 120° load zone (III).

MOUNTING PRACTICES.

Most gearbox manufacturers provide installation and maintenance manuals with precise mounting procedures which must be thoroughly followed. The following comments, however, are general guidelines to make the handling of large bearings easier, more productive and safer:

PRIOR INSPECTION:

· Shaft and bore diameters must be within the specified tolerances;

· Shaft and bore surfaces must be within roundness and flatness tolerances. Check diameters at 0, 45°, 90° and 135° around the circumference and in four places along the surface;

· Shafts and bores must be clean and free of nicks, sharp edges. burs or rust;

· Chamfers and corner radii must be within specifications;

· Bearing shoulders must be square and in the proper height; and

· Bearings must meet application specifications (complete bearing number);

MOUNTING INNER RINGS WITH TIGHT FITS:

· Large bearings mounted on tight fit shafts need to be heated. Whether in oil bath, induction furnace, flame or oven:

o Plant environmental and safety procedures must be followed;

o Component temperature must remain below 110°C; and

o Temperature must be even around and within the bearing rings (this may take several hours for larger bearings).

· Proper tools are required to handle large components at high temperatures;

· Install the bearing with a quick but careful motion. It is simple when done properly, but it may be very difficult to remove a bearing that cools down skewed or out of position;

· Keep pressure on the bearing against the shoulder until it has cooled down, this will prevent the beating from moving away from its proper position while it is still hot.

CONCLUSION.

Bearings are high precision components that must be handled properly and must be mounted on shafts and housings that meet design specifications. Bearing internal clearance is an important specification because It has direct impact on the smooth operation of the gear mesh and on the life expectancy of bearings and gears. Bearing internal clearance in the free state is set at the factory for unit bearings or it is set during gearbox assembly for separable and angular contact bearings. The actual operating clearance is the result of the reduction of free sate clearance due to shaft or housing tight fits and to a differential thermal expansion of these components. Ideally, bearings should operate under a slight preload, however, trying to achieve this condition comes at a high risk of premature failure. It is, therefore, a more conservative and widely followed engineering practice to aim for a small clearance in operating conditions. A smooth and trouble-free gear operation requires complying with specifications for all components and following proper preparation, inspection and mounting procedures.

REFERENCES:

Arvid Palmgren, Ball and Roller Bearing Engineering, SKF Industries.

No hay comentarios:

Publicar un comentario